Today’s building owners, operators, and developers are adjusting to a new market environment in a post-pandemic world. Many are reexamining traditional functions of their facilities as tenants demand greater flexibility, connectivity, comfort, health, and safety. Integrating an intelligent domestic water system can have an impact on all those areas.

Smart buildings use a wide range of existing technologies to facilitate the efficient and economical use of resources. Critical equipment such as lighting, air handlers, chillers, and boilers communicate with one another through a sophisticated management system that monitors various components. They do this by collecting and sharing data between systems.

The goal is to provide useful services that minimizes environmental impact while also helping occupants to be more productive and safer. And while your first thoughts may go to energy monitoring and HVAC (heating, ventilation, and air conditioning) controls, a growing awareness of intelligent domestic water systems is trending—and for good reason. While conservation continues to be a key consideration, it is not the only one.

Conserving Water Safely

According to recent reports from the U.S. Environmental Protection Agency (EPA), water use in commercial and institutional facilities (e.g., office buildings and hospitals) account for 17% of publicly supplied water in the U.S. For these properties, restrooms, heating and cooling, and landscaping accounts for most of the use. Strategies to increase savings and efficiency include:

- Harvesting rainwater, graywater (gently used water from bathroom sinks, showers, washing machines, etc.), and other non-potable water sources for outside irrigation and flushing applications.

- Implement energy-efficiency measures to reduce the need for building and equipment cooling and heating, which will reduce amount of water required by these systems.

- Installing more efficient fixtures (such as dual flush toilets, sensor-controlled faucets, etc.)

However, I want to place a huge caveat on the third bullet point. Before rushing out to install a bunch of low-flow fixtures to save water, be advised that doing so in haste could be putting building occupants at risk. Today’s water pipe sizing practices are outdated and don’t consider the decreased volumes of water used by widespread low-flow fixtures. These devices can leave water in the pipes and increase building water age. Stagnant water in these systems can create an environment ideal for cultivating dangerous pathogens, including the bacterium responsible for Legionnaires’ disease.

When water was flowing at higher volumes thru the plumbing systems, the water purveyor’s primary and secondary disinfectants had the best chance at eliminating water borne pathogens because the disinfectants used have a shelf life. The use of low flow fixtures in conjunction with outdated water pipe sizing practices allow the disinfectants to expire before the water reaches your faucet. As a result, pathogens are given the opportunity to grow and multiply inside the building pipes.

The fixture unit method referenced in most plumbing codes to calculate water pipe size is based on the outdated Hunter’s Curve, developed back in the 1940s when plumbing fixtures were consuming water at much higher volumes. The plumbing engineering community must question why we are using a calculation method which fails to reflect the reality of today’s low flow plumbing designs.

Building owners and managers should work with design engineers to correctly size the piping infrastructure of their facilities using tools like the Water Demand Calculator. While this tool is recognized for only certain building types in the Uniform Plumbing Code (UPC), it is a starting point to keeping water moving in buildings and recognizing that fixtures are flowing lower than they were in 1940. Only then, can we reasonably recommend a holistic use of water conserving fixtures. They are important but keeping buildings healthy is more important.

While conserving water by establishing an intelligent water system can be an important factor, it is much more than that. The health and safety of building occupants should be the prevailing motivation.

Increased Focus on Health and Safety

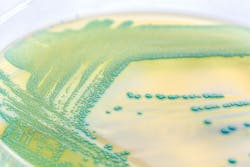

Legionella is a general category of bacterium all-too-commonly found in our water supplies. There are over 60 different species of bacterium, of which 25 are known to be implicated in human disease. There is one king of the species, Legionella pneumophila, that is responsible for approximately 90% of all infections. About 1 out of every 10 people diagnosed with Legionnaires’ disease will die due to complications from their illness. For those who get Legionnaires’ disease during a stay in a healthcare facility, the mortality rate climbs to about 1 out of every 4.

Building owners and operators have good reason to be so concerned about Legionella as plumbing domestic water systems are the predominant source of the bacteria. If Legionella grows in a plumbing system, the bacteria can spread to humans via small droplets and/or vapor inhaled into the lungs. Common sources where these droplets are “made” include:

- Showerheads and sink faucets

- Cooling towers

- Hot tubs

- Decorative fountains and water features

- Hot water tanks and heaters

- Large, complex plumbing systems

So how do the bacteria grow and spread? Water temperature, disinfectant residual, stagnation, and quality as well as pipe materials and other factors can all contribute to the development of Legionella pneumophila growth in the domestic water system. The larger and more complex the building is, the more challenging it is to maintain a healthy, balanced system. Complicating this further, the age, location, surrounding environment, and incoming water quality can also have a significant impact on the development of Legionella bacteria.

Legionella bacteria have an ideal temperature range for growth which also happens to be right in the sweet spot most building occupants favor for washing, bathing, showering, or soaking in a hot tub. And if the building occupants are in a higher risk category, you may have to consider more options, such as supplemental disinfection to keep occupants safe.

ASRAE offers a guide to “Legionellosis: Risk Management for Building Water Systems,” which it describes as “essential for anyone involved in design, construction, installation, commissioning, operation, maintenance, and service of centralized building water systems and components.” Likewise, the U.S. Center for Disease Control and Prevention (CDC) offers its “Toolkit: Developing a Water Management Program to Reduce Legionella Growth and Spread in Buildings.”

Economic Benefits

In addition to making buildings safer, healthier, and more ecologically responsible, implementing a smart water system can have other positive impacts on a company’s balance sheet. Planning for the adoption of an intelligent system can uncover problems, such as previously undetected leaks or malfunctioning equipment, that may have otherwise gone unnoticed. More comprehensive metering can also identify areas to target reduced water use.

Establishing and communicating water conservation and efficiency measures can also position building owners, managers, and companies as leaders helping to improve sustainability. Implementing best management practices for water efficiency can earn recognition for facility owners and managers in the green marketplace.

For a water management program to succeed, there should be a comprehensive strategic plan and vision in place. Understanding your current water uses and systems allows you to develop a plan for greater water conservation, efficiency, management, and health and safety. Having clear objectives also helps your organization set priorities to allocate project funding to have the greatest impact.

James Dipping, PE, CPD, ARCSA®AP, GPD, LEED AP BD+C, is the technical director of plumbing engineering for ESD, a leading global engineering firm specializing in mechanical, electrical, plumbing, fire protection, life safety, structural, and technology engineering. James has more than 25 years of experience in the plumbing design and construction industries. His main responsibilities include training development and engineering standardization, specification maintenance, design programming, project management and team leadership, client relations, and quality. James is a licensed Professional Engineer (PE), has spoken at American Society of Plumbing Engineers (ASPE) Tech Symposiums, and has published several articles in many industry magazines on various topics related to plumbing engineering.

About the Author

James Dipping

Technical Director of Plumbing Engineering - ESD

James Dipping, PE, CPD, ARCSA®AP, GPD, LEED AP BD+C, is the technical director of plumbing engineering for ESD, a leading global engineering firm specializing in mechanical, electrical, plumbing, fire protection, life safety, structural, and technology engineering. James has more than 25 years of experience in the plumbing design and construction industries. His main responsibilities include training development and engineering standardization, specification maintenance, design programming, project management and team leadership, client relations, and quality. James is a licensed Professional Engineer (PE), has spoken at American Society of Plumbing Engineers (ASPE) Tech Symposiums, and has published several articles in many industry magazines on various topics related to plumbing engineering.