Latest from Residential Plumbing

Leap Partners Continues Expansion in North Carolina

Sponsored

Water heater manufacturers are ready for new residential efficiency standards

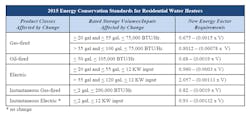

New residential water heater energy efficiency standards are coming quickly for the manufacturers, distributors, wholesalers and contractors that produce and install these appliances. In less than one year, the new minimum energy efficiency standards will be in effect for water heaters manufactured after April 15, 2015.

The 2010 Department of Energy Final Rule on energy efficiency mandates a higher Energy Factor (EF) rating on virtually all residential water heating products, including gas, electric, oil and tankless gas water heaters.

According to The Energy Efficiency Standards group, the efficiency metric for residential water heaters is the Energy Factor (EF), which indicates a water heater's overall energy efficiency based on the amount of hot water produced per unit of fuel consumed over a typical day.

The EF accounts for recovery efficiency — how efficiently the heat from the energy source is transferred to the water; standby losses — the percentage of heat loss per hour from the stored water compared to the heat content of the water (for water heaters with storage tanks); and cycling losses — the loss of heat as the water circulates through a water heater tank, and/or inlet and outlet pipes.

According to Karen Meyers, corporate director of government relations at Rheem, the DOE is required to review efficiency standards to determine if the higher efficiency rate can generate enough energy savings.

“There are all types of things DOE has to do to make sure a new minimum efficiency level can be justified,” says Meyers. “Typically rule making takes about two years, and Rheem has been very involved with this process from the very beginning.”

Navigating the National Appliance Energy Conservation Act

According to Harvey Sachs, Ph.D, senior fellow, at the American Council for an Energy Efficient Economy, the 55-gallon mark will be a transition point.

“The DOE decided to separate out larger water heaters used presumably by people who have larger water use,” says Sachs. “When you look at larger water users it becomes cost effective to require heat pump water heaters for electric service and condensing tank technology for gas service (condensing is not required for gas tankless), and that is what DOE has done.”

Redesign/design process

In 2010, residential water heater standards were announced to take effect in 2015, and once manufacturers heard of the news, they started allocating resources to start product redesign and new product design. Many manufactures have had to change the manufacturing process to create these new products, plus, create new marketing and training materials.

A. O. Smith has been preparing for these changes several years in advance.

“There is a lot of work involved, but there has not been any big surprise with the regulations,” says Charlie Adams, chief engineer and director of government affairs at A.O. Smith. “We didn’t encounter anything that was not anticipated. We currently have several models that already are compliant, including condensing gas and heat pump technologies, and we are well on our way to having more products that meet the standards. We did have models we redesigned. We have been continuing to work in the lab to get the remainder of the product offering in shape.”

Bradford White realigned its engineering resources very early on in anticipation of this industry change.

“Bradford White has been busy developing the best solution for our customers,” explains Chad Sanborn, product marketing manager at Bradford White. “Although many Bradford White water heaters on the market today currently meet the updated NAECA (National Appliance Conservation Act) standards, many more products are being designed and redesigned to meet NAECA’s 2015 efficiency requirements.

“There are new products currently being developed that are not on the market yet,” adds Sanborn. “These products will meet the new EF requirements as we know it today. The challenge facing the industry now is getting a final decision regarding new Uniform Test procedures. These new procedures will alter the way products are tested to achieve the new EF requirements, and have a large impact on the way the products are designed.”

According to Sanborn, Bradford White customers always want energy efficient products, thus, Bradford White has always developed energy efficient water heaters.

“Regardless if energy efficiency is mandated by the DOE, the customer wants their water heater to be as efficient as possible without sacrificing too much hot water deliverability,” says Sanborn. “If this new regulation was never implemented, manufacturers most likely would still continue to develop new products to increase EF ratings.”

Adams agrees that there is consumer demand for energy efficient products.

“At A.O. Smith, we have focused on innovating in the category of energy efficiency for many years.” says Adams. “The ‘sweet spot’ is being able to deliver a better performing water heater while enhancing its overall energy efficiency.”

When a manufacturer creates a product to meet these energy efficiency requirements, so many variables are considered in the process.

According to Adams, just about everything is looked at when designing a new product.

“We do consumer focus groups, contractor interviews, etc., to understand what the value is, from the end-user to the contractor that installs it to the wholesaler that sells it,” explains Adams. “Of course safety, reliability and performance are first and foremost. We look at many aspects as the market changes.”

Also, all aspects of the water heater and where it will be installed are considered when developing products to meet increased EF ratings.

Replacement market

Many manufacturers forecast that the replacement market will be hardest hit.

Sachs thinks that there may be push back in the replacement market too.

“I understand that for electric water heaters a significant amount of sales are via big box stores, but a lot of those are installed by contractors,” says Sachs. “I would expect that the legally mandated water heaters will be carried by big box stores, but consumers will be discouraged from installing them on their own.”

Increasing efficiency may also affect the size of the water heater.

“It has become common practice to tuck away the water heater into a corner or alcove in an effort to reduce the amount of floor space used,” explains Sanborn. “As products grow in size, customers will be faced with a decision to either relocate the water heater, reconstruct the water heater surroundings, or downsize the capacity. Bradford White will be sure to provide products that will be a solution to any decision the consumer makes.”

“When a water heater gets more efficient sometimes it gets larger,” explains Meyers. “When that happens there are always concerns about replacement. In the larger volume water heaters it’s new technology to meet a federal minimum. In a large volume electric water heater it will need to be heat pump technology vs. a large storage electric water heater.”

For gas water heaters, the large volume will be required to be a condensing water heater because of the gas requirement.

“When you have condensing technology, you are replacing an old large gas water heater with a new water heater with condensing technology,” says Meyers. “In this case there needs to be provisions for a drain because of condensate. I think there will be challenges like this, but they can be solved. However, it may drive up replacement costs in some instances. But the DOE tries to look at that in their analysis and evaluate it before they come up with their rule making.”

Electric water heaters larger than 55-gal. will be heat pump water heaters.

“It’s like an A/C heat pump in that it takes heat out of the air, and in the case of a water heater, puts it in the stored water. It needs sufficient air circulation around the heat pump to have enough of a heat reservoir to work effectively,” explains Adams. “Enough air needs to be available to take the heat out and put it into the water, and that means the heat pump water heater is not necessarily well suited for installation in very tight spaces. You need sufficient airflow around it. We made this comment to DOE during the rule making process that lead to the standard, and this continues to be an installation concern.”

Another installation concern is the thickness of insulation around the tank.

“There are some types of water heaters that are designed to go into very tight spaces that don’t have an extra 2-in. of room, so this can create a fit problem,” says Adams.

Tankless

For tankless water heaters, the DOE has chosen to raise the EF standards from 0.62 to 0.82, which is the largest increase of any of the water heater products, and according to James York, vice president of engineering at Rinnai America Corp., this is being done in response to tankless water heater manufacturers already achieving Energy Star rating standards at 0.82.

“This is the first time the DOE has segmented the gas and electric water heater market by different types or volume,” says York. “The new federal standards announced in 2010 affect all types of water heaters. This increase will push tankless water heater energy standards even higher — 25% to 35% — than traditional tank-style water heaters.

York also points out that the DOE is in the process of writing a new testing method for rating traditional tank-style and tankless residential water heaters.

“We expect to see the final draft of the test procedure in the near future,” says York. “So in addition to meeting new federal minimums, manufacturers will need to adjust to changes as a result of the latest testing method.”

York adds that the obvious pros of the new federal minimum efficiency standards are reduced energy costs for consumers and a reduced energy burden on the country, as a result of higher-efficiency products.

“We have seen tremendous growth the past decade in high-efficiency products, such as condensing and non-condensing tankless water heaters,” says York. “This growing trend is driven by consumers’ desire for lower utility costs and high-efficiency products and homes, and the Home Energy Rating System (HERS).”

Training contractors

Manufacturers are offering contractors many training opportunities to get them up to speed on installing the redesigned and new products that meet the new efficiency standards.

“We see the contractor as the key decision maker as to what tankless product is installed, and the training is so important,” says Eric Ashley, product marketing supervisor, at Navien. “Tankless is still a small percentage of the market in general, so it’s so important that we train contractors.”

Navien offers a tankless water heater with an EF of 0.98 and another product with an EF of 0.97.

“All of our tankless products currently have a substantially higher EF than the new standard,” says Ashley. “Navien focuses on the replacement market since this makes up the largest percentage of the water heating market. We have engineered our products for the replacement market.”

Navien makes training contractors a priority. “We want the most educated installers out there,” says Ashley. “It creates less callbacks for the contractors and they are comfortable installing the product, too, so they want to install tankless more.”

Bradford White has been engaged in educating the plumbing industry about this change since 2012.

“Most importantly our sales force has hit the street to talk about this important topic with our customers both face-to-face as well as at many industry conventions such as local and national PHCC events,” says Sanborn. “Plus, we provide hands on training at our iTEC facility located in Middleville, Mich. Contractors and wholesalers are able to turn wrenches and ask questions about some of the newer technologies that will be required, such as condensing gas or electric heat pump technologies.”

Rheem offers many different training courses that plumbers and contractors can take to learn about new technology.

“We are making sure wholesalers and contractors understand these regulations and what they mean,” explains Meyers. “We have a wide variety of products that meet the federal minimum that are incorporating new technologies that we are very proud of.”

According to York, sometimes the contractor needs a different mindset in order to give the customer options on an install.

“We have a very extensive training program at Rinnai,” says York. “We have a training facility at the Rinnai headquarters in Peachtree City, Ga., where we host installation, troubleshooting, and hands-on product tear down seminars to educate installers on our tankless water heaters. We also offer an online university training program helping to bring education to installers nationwide. In addition, we also have regional service managers that offer sales training to contractors and distributors.”

At A.O. Smith, they have invested a tremendous amount of resources towards training trade professionals in the development of a digital classroom — A.O. Smith University. This studio enables A.O. Smith to conduct virtual training sessions across the country in an interactive classroom setting via live streaming video.

The industry is ready

“One of the greatest engineers I have ever met once told me, ‘A good engineer plans for what will go right. A great engineer plans for what might go wrong,’ ” says Sanborn. “Even though Bradford White has been educating our customers for the past two years on these new regulations, we will not stop. Our customers are more educated today on this subject than when this news first hit the industry in 2010 and have a much better grasp on the subject; however, continued training and education is a must. It is our commitment to the plumbing industry to help wholesalers and contractors be successful, and that will be achieved through continued education on topics such as the raised minimum EF standards.”

According to Meyers, the industry is ready for this change.

“The rule was finalized back in 2010 and we have had five years to comply, so I think the industry as a whole is ready to go,” says Meyers. “It’s a big job since product designs need to be changed along with the manufacturing processes. There is a lot to getting it all in production and certified. A manufacturer has to test the building materials, qualify new suppliers, etc. There are many steps a manufacturer has to go through for changes like this, and this is just on the manufacturing side to develop the product. Plus the manufacturer needs to create new marketing materials, training programs, etc.”

“Rinnai is 100% ready for the 2015 standards going forward with our condensing and noncondensing line,” says York. “And as an industry, as a whole, I would say we are mostly ready. Next is the new test method of rating residential water heaters, which will require a lot of education to the contractor base.

“Rinnai’s condensing and non-condensing tankless water heaters already meet or exceed the 2015 standards,” adds York. “And as an industry, I would say we are mostly ready. With the new testing method, as with any new technology or regulation, education of the contractor base will be integral in continuing the growth of tankless water heaters in the residential market.”

Candace Roulo

Candace Roulo, senior editor of CONTRACTOR and graduate of Michigan State University’s College of Communication Arts & Sciences, has 15 years of industry experience in the media and construction industries. She covers a variety of mechanical contracting topics, from sustainable construction practices and policy issues affecting contractors to continuing education for industry professionals and the best business practices that contractors can implement to run successful businesses.