Latest from Piping

Sponsored

The behind-the-wall framework of a home contains a vital plumbing system that keeps it running efficiently and safely. Within every residential plumbing system you have subsystems that include water-supply pipes, drain pipes, vent pipes, and gas lines.

Each subsystem acts as a key component in the complexity of water supply, waste removal, and more. The water coming into the home (potable water)—either from a well or from a public utility company (water purveyor)—is called the water supply.

From a master bathroom shower to the basement toilet, the water supply system circulates water throughout the home efficiently by the touch of a button or a simple turn of a handle. A structure of pipes, ranging from ¼” to 1-¼” inches in diameter, supports the distribution of this water.

Whether you’re a new pro entering the industry or a seasoned plumber in need of a quick refresher, this article will provide an overview of the types of piping responsible for routing water supply. It will also help you select the most effective and efficient pipe-joining methods and products for each pipe job.

Copper

Commonly used, copper pipe offers a lightweight portability that can be easily transported to and within a home. With their high thermal conductivity and durability, copper pipes provide long-term reliability to homeowners.

Although the properties of copper pipe offer some corrosion resistance, corrosion can manifest over an extended period of time. We recommend advising homeowners to conduct annual inspections to locate any leaks that can occur over time and avoid corrosion-related health hazards.

This durable metal contains formable properties that allow the pipe to bend and form to your liking; however, when copper tubing requires connection, you can easily solder these pipes and fittings.

Soldering (or sweating) is a critical step in the copper-installation process. Solder is a metal or alloy that historically consisted of lead (known as lead-based solder) and tin in various proportions. Today, due to the Safe Water Drinking Act and lead-free restrictions, solders that contain more than 0.2% lead are not permitted for use in potable water systems.

Solders that are safe to use on potable water systems contain a percentage of tin and a combination of other nontoxic metals. The melting point of solder is lower than copper, and when heated, solder melts and fuses the piping together once completely cooled.

In addition to choosing the proper type of solder for your application, you will need to select the right type of copper pipe and flux, a compound that promotes the flow of molten solder between the pipe and fitting through a process known as capillary action.

Flux is also formulated to remove any oxidation from pipe and actually etches pipe surface in preparation for the soldering process to be successful. Important variables, such as pressure and temperature, local code guidelines and any job-site time limitations, should all be considered prior to purchasing your soldering supplies.

Learning how to solder copper pipe can seem daunting at first, but by applying proper techniques and avoiding typical errors, it becomes much easier to execute a leak-free pipe joint

Some common mistakes professionals make during the soldering process include using the wrong products, skipping prep, applying too much flux, overheating the joining, and neglecting cleanup.

Below are some brief product guidelines to keep in mind for your next copper pipe project.

Types of Copper Pipe

● Type K: This type has the thickest wall and strongest durability. It is commonly used for commercial plumbing, such as underground water mains for potable water supply and HVAC lines.

● Type L: Wall thickness falls between Type K and M. Typically used for interior hot and cold-water distribution.

● Type M: Has the thinnest wall and is the most popular choice for domestic plumbing systems due to its light weight, decreased rigidity and affordability.

● Copper DWV: Commonly used in older homes for vents and drains, it is no longer a popular choice among modern-day homeowners, as there are more cost-effective options available.

Types of Flux

● Petroleum-based Flux (or Petrolatum Flux): Flushing is required with this flux, which is designed to provide● Hot Weather Flux: Specially formulated for hot weather climates, this flux will not separate in temperatures up to 135°F.

● Water-soluble Flux: Water flushable, this flux is compatible with all common plumbing solder alloys.

● Tinning Flux: Available in both water-soluble and petroleum-based formulas, this flux is enhanced with tinning powder particles to pre-tin piping and improve the flow of solder, as well as enable even heating of a fitting. The latter is necessary when soldering larger diameter piping systems. This flux is compatible with all common plumbing solder alloys.

Although petroleum-based fluxes are safe to use, they are required to be flushed with a chemical solution from the piping system due to their water insolubility. However, water-soluble fluxes become self-cleaning and flush away once water enters the system. Refer to manufacturer instructions for product-specific application and safety guidelines to ensure proper use.

Types of Solder

● Tin-antimony Solder: Contains 95% and 5% antimony, this solder is lead-free and safe for water supply lines. Designed for use in plumbing applications where frequent extreme temperature changes and vibrations occur (refrigeration, cooling equipment and heat ducts); can also be used to solder electronics, tin-antimony solder has a melting range of 450°F to 464°F. Has an unlimited shelf life.

● Copper-tin Solder: Contains 97% tin and 3% copper. Lead-free and safe for water supply lines. Designed for sweating copper and brass plumbing joints. Melting range is 440°F to 572°F. It has an unlimited shelf life.

● Silver-bearing solder: Contains silver, copper, bismuth and tin. Lead-free and safe for water supply lines. Ideal for low-lead brass applications. Has a wide melting range (420°F to 460°F) that enables more time for soldering joints.

PEX (plastic)

This flexible plastic material can bend around corners and through walls and floors, connecting to a PEX manifold that is itself connected to the main water supply, thereby eliminating the need to make a pipe connection every time there is a change in direction.

PEX is also corrosion-resistant and can expand, offering resistance to cracks as temperatures drop to freezing. Often marked with a lacquer finish—colored red or blue to distinguish between hot and cold supply lines—PEX can be connected to existing metal supply lines using the appropriate fittings, eliminating the need for soldering completely.

PEX pipe and fittings range from ¼-inch to 1-¼” inch copper tube size (CTS) in both inches and metric diameters, with hydrostatic pressure ratings of 160 pounds per square inch (psi) at 73°F and 100 psi at 180°F.

CPVC (plastic)

CPVC sizing options range from ½"-to 2" copper tube size (CTS) and pipe sizes from ½"- to 2", with hydrostatic pressure ratings of 400 psi at 73°F and 100 psi at 180°F.

The chlorine present in CPVC resists bacteria from forming within the pipe before the water enters a home. It offers superior mechanical strength in residential water systems, effortlessly connecting with other pipes and fittings with easy use of solvent cements.

Some common mistakes professionals make during the solvent welding process are not choosing the right cement for the job, not preparing the pipe properly, skipping primer or applying it improperly, not waiting for the appropriate set-and-cure time, and, finally, not having adequate airflow.

Below are some brief product guidelines to keep in mind for solvent welding.

Before selecting solvent cement, consider the following:

Pipe Material: First, determine if you will be joining CPVC, PVC (Polyvinyl Chloride) or ABS (Acrylonitrile Butadiene Styrene) plastic pipes before selecting the corresponding cements. For example, use CPVC cement for CPVC pipe fittings; ABS cement for ABS pipe fittings.

This is arguably one of the most critical steps in the solvent-welding process. If a cement and pipe material aren’t compatible, then the pipe and fitting cannot chemically fuse together. That, in turn, will lead to joint failure and potentially damaging leaks.

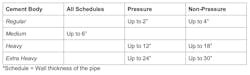

Pipe Size: Next, consider the thickness of the pipe. Thicker pipe will require a cement with a thicker viscosity, or a heavier body. You can choose from regular, medium and heavy bodied cements.

As a general rule of thumb, our experts recommend using the following pipe size guidelines when selecting a solvent cement. You can also find the maximum recommended pipe size listed on the cement can.

Application Conditions: Additionally, confirm that a cement is rated for the temperature, moisture and pressure conditions of the application site. You should also consider whether you’re working on a potable water system or a non-pressurized DWV (Drainage, Waste and Vent) system. Then select the cement formulated for that particular application.

Cement set and cure times should also be evaluated. For example, if you have a time-sensitive project where the plumbing system cannot be down for an extended period of time, opt for a faster-setting product.

Local Codes and Standards: Finally, ensure the solvent cement meets all applicable codes and standards based on application site.

Oatey offers a range of solvents cements for joining CPVC:

Orange Lava CPVC Cut-In Cement: A fast-setting cement formulated for time-sensitive repair-and-cut-in work, this one-step cement does not require a primer where local codes permit. It is heavy-bodied for use on all schedules and classes of CPVC pipe and fitting up to 6’’.

FlowGuard Gold 1-Step Yellow Cement: Ideal for CTS (Copper Tube Size) cold and hot potable water pipe andMedium Orange CPVC Cement: Suggested for both residential and commercial cold and hot water systems with temperatures up to 200°F / 93°C, this cement is approved for use on all schedules and classes of CPVC pipe and fitting up to 6’’ and requires the use of primer.

High Contrast 1-Step CPVC Cement: FlowGuard™ High Contrast 1-Step All Weather Fast Set Green Cement is recommended for cold water systems and hot water systems up to 200°F / 93°C. Its prevention formula is designed to help protect pipes from corrosion. Its green color provides high contrast to CPVC pipe, making it easy to identify proper installation. This low VOC, fast set cement can be used to solvent weld copper tube sizes (CTS) CPVC hot and cold potable water pipes and fittings up to 2 in. diameter with interference fit.

Galvanized

Commonly installed in homes built before 1960, galvanized pipes were made of steel dipped in protective zinc to prevent corrosion. Less costly than copper, this type contains wider diameters, allowing higher flow rates through it.

Hard water contains calcium carbonate that, when combined with zinc carbonate, forms a protective layer on the pipe, rendering it resistant to corrosion. However, this protective layer will deteriorate over time, which can lead to water-system failure.

Soft water does not contain calcium carbonate. As this type of water moves through the pipe, it damages the protective zinc layer, leaving the galvanized steel vulnerable to corrosion and rust. This shortens the lifespan of the pipes more quickly than hard water.

For all these reasons, we recommend that you replace galvanized pipes with one of the previously discussed options to ensure the home water system functions optimally and is free from health hazards.

Conclusion

Now that you have been briefed on the various types of plumbing pipes used for water-supply systems, be mindful of external conditions that can disrupt such a plumbing system in a home. For example, use appropriate materials to secure the piping in your home, such as supply hangers.

Just as importantly, remember that the efficiency of a water-supply system requires regular maintenance. This is the best way to maintain the longevity and optimal performance of a system, regardless of pipe type.

Sean Comerford is Applications Manager at Oatey Co. He is third-generation tradesman with nearly 20 years of plumbing experience, including serving as the lead plumber for commercial/residential new construction, service and fire protection jobs. He holds a State of Ohio Fire Protection License for Sprinkler and Standpipe.

Sean Comerford | Applications Manager - Oatey Co.

Sean Comerford is Applications Manager at Oatey Co. He is third-generation tradesman with nearly 20 years of plumbing experience, including serving as the lead plumber for commercial/residential new construction, service and fire protection jobs. He holds a State of Ohio Fire Protection License for Sprinkler and Standpipe.