Latest from Piping

Sponsored

By Jonathan Simon

Plumbers today don’t live in a one-material world. When working with different builders, or especially when making service calls, they may be required to work with copper, CPVC or PEX. Moving successfully between these materials requires a base understanding of the differences between them, including the right tools to use with each and how different materials respond to temperature, pressure and water conditions.

These challenges are particularly prevalent when dealing with the two plastic piping systems in use today, PEX and CPVC. There’s a tendency to think that because the two materials are both categorized as plastic, they are more similar than different. In fact, there are significant differences between the two and its these differences that plumbers need to be aware of when working with each material.

Chemical Composition

Without getting too deep into chemistry here, it’s worthwhile to review some basics because material chemistry can affect performance. One example is polybutylene, a plastic piping material used in new construction throughout North America in the 1980s. This material proved unsuitable for residential water systems because of an inherent chemical incompatibility with chlorine. It was eventually removed from the market and most of it has required replacement because of chlorine-related failures.

PEX is from the same polyolefin family of polymers as polybutene but is manufactured using a polyethylene base with cross-links between the polymer chains. PEX manufacturers also use chlorine inhibitors to mitigate incompatibility issues between the material and water treatment additives. Still, the material can be susceptible to chlorine degradation, particularly in aggressive water conditions. PEX is also softer and more flexible than either copper or CPVC and uses a different style of fitting than either of those two materials.

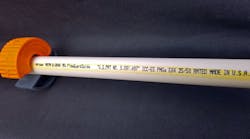

CPVC stands for Chlorinated Polyvinyl Chloride and because the material is chlorinated, it is immune to the chlorine-related problems that can exist in copper and PEX. CPVC is somewhat flexible when new, simplifying installation for plumbers, and becomes more rigid over time. Rated to handle 400 psi at 73° F/23° C and 100 psi at 180° F/82° C, it can be used in some applications that aren’t ideal for PEX, such as temperature and pressure relief lines, condensate drains and hot chlorinated water.

Using the Right Tools

Surprisingly, the number one problem plumbers have when dealing with PEX and CPVC is using the right tool for cutting. When we conducted an online quiz designed to test plumbers’ knowledge of the two materials, roughly half indicated they would use the wrong tool to cut into the pipe for service.

This should be an easy issue to fix and companies like Lubrizol Advanced Materials, manufacturer of FlowGuard Gold® CPVC, are committed to providing clear, straightforward information to help ensure plumbers always use the right tools when cutting plastic pipe.

PEX piping can be cut with ratchet cutters or scissors-style shears, but many plumbers suggested they could also use normal c-style tubing cutters for this material. Because PEX is a soft plastic, only a c-style tubing cutter specifically designed to work with plastics can effectively cut into PEX tubing.

For new CPVC, ratcheting cutters or a c-style tubing cutter should be used. Because CPVC becomes more rigid as it ages, aged CPVC should be cut with a c-style tubing cutter, or alternately a wheel cutter or a fine-tooth saw. A non-ratcheting, scissors-style pipe shear should never be used on CPVC in either new construction or service.

Working with Fittings

CPVC uses a solvent weld process to secure fittings to pipes, similar to copper fittings but without the need for soldering, which can be messy and introduce a fire hazard. Most plumbers adapt easily to this process because of their familiarity with copper fittings, but there are a couple of things to keep in mind when installing CPVC fittings.

First, to ensure an even coating of solvent cement, use a dauber one-half the size of the pipe diameter. The other thing to know is that there are solvent cements specially formulated for servicing CPVC as opposed to those used when installing new CPVC. Both formulations form an exceptionally strong bond when applied correctly but the formulations designed for service cure faster, reducing wait times and allowing service plumbers to finish jobs more quickly.

With PEX, the pipe fits around the outside of the fitting so the internal diameter of the pipe is reduced at each fitting even when “full flow” expansion fittings are used. Depending on the fitting used, this can reduce the internal diameter of a ½” pipe anywhere from 21 percent to 35 percent, which can have a noticeable impact on water pressure. Using PEX to replace a copper or CPVC system can result in unwanted pressure drop or require the use of upsized pipe to maintain system performance.

Diagnosing Problems

Understanding material characteristics and how they impact performance can also eliminate the need for unnecessary repairs and improve the ability to diagnose problems.

As mentioned previously, CPVC’s pressure-bearing capability increases with time and the material has inherent immunity to the chlorine degradation. Provided it was installed correctly, aged CPVC pipe, even if it appears brittle, can continue to deliver reliable performance and does not need to be replaced.

When they do occur, CPVC pipe failures can indicate pressure or temperature problems within the system as the pipe would not be expected to fail under normal conditions. One thing to look for is a malfunctioning boiler or water heater that is overheating the water to over 200° F. This is not only a problem for the pipes, it could be dangerous to residents of the home. Other potential causes of CPVC failure may include failure to account for thermal expansion and contraction in the initial design of the system, or exposure to aggressive chemicals which are incompatible with CPVC—similar to the process of galvanic corrosion in copper caused by dissimilar metals.

Another example is the common misconception that UV light causes PEX failures. UV light can contribute to chlorine-related failures in PEX; however, it doesn’t actually cause the failure. UV light acts as a catalyst for the oxidation process that consumes the chlorine-inhibiting antioxidants that protect the pipe from chlorine induced oxidation. As these chlorine inhibitors get consumed, piping is left vulnerable to attack from chlorine in the water. If you simply replace a failed pipe thinking the problem was UV light exposure, you could be ignoring broader water incompatibility issues within the system and end up coming back in a few years to replace the pipe you put in.

Plumbers today have to shift from working with copper to PEX to CPVC, sometimes in a single workday. With the increased use of plastic in new construction, they are working on more plastic piping than ever. Understanding the fundamental differences in the proper procedures and performance of CPVC and PEX allows you to work more efficiently and ensure the satisfaction of your customers.

To help plumbers access training and education on servicing CPVC, the FlowGuard Gold team has created an online information hub specifically for service plumbers at FlowGuardGold.com/ServiceSuccess.

Jonathan Simon is the North American Residential Plumbing Manager for Lubrizol Advanced Materials, Inc. Lubrizol Advanced Materials products create and/or improve the performance of our customers’ products and enable unique performance attributes. For 60 years, FlowGuard Gold® Pipe and Fittings have provided reliable hot and cold water plumbing systems to residential and commercial buildings and are the preferred choice of plumbers and distributors because of their quick, easy installation, system compatibility and proven track record. For more information, visit www.flowguardgold.com.