Latest from Piping

Sponsored

By John Stephenson

Chlorinated polyvinyl chloride, or C-PVC, is commonly used in construction due to its high heat deflection temperature, resistance to corrosive chemicals and relative low cost. C-PVC is available in both nominal pipe sizes, and copper tube sizes. While copper tubing can corrode, is expensive to buy, and is prone to theft due to high scrap value. C-PVC is 100 percent corrosion resistant and inexpensive compared to metallic piping. Due to its chemical makeup, C-PVC outperforms other plastic alternatives in the presence of a fire, which has led to its widespread adoption. (1)

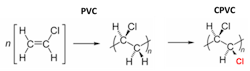

To create C-PVC, a free radical chlorination reaction is created by adding chlorine to PVC in a water slurry or fluidized bed reactor. The chlorination reaction is initiated by ultraviolet light. After the resin is chlorinated, Chlorine (Cl) atoms make up 40% of the bonding sites of the C-PVC molecule. It is these additional large Chlorine (Cl) atoms which provide additional resistance from thermal & chemical attack, protecting the carbon backbone from breaking down.

C-PVC tolerates higher temperatures (200 °F vs. 140 °F) and is significantly more flexible than PVC. C-PVC piping is used for hot water, strong acids, and high pH caustics. In addition to the unique thermal and chemical properties, C-PVC provides greater insulation than metallic pipes, which maintain the temperature of the fluid more efficiently, and results in less condensation.(2)

As many building codes began to address the use of plastic pipe in fire resistive construction, demand for C-PVC’s characteristics became widespread. ASTM E 84 established requirements for Flame-Spread Index (FSI), Smoke Development Index (SDI.)

The International Building Code (IBC) requires interior walls and ceilings are in compliance with ASTM E-84. The International Mechanical Code (IMC) similarly requires all plenums to comply with the ASTM E-84 25/50 requirement (explained below). There are exceptions to these requirements for single- and two-family dwellings, and combustible materials which are enclosed within approved materials or assemblies, but the majority of new buildings must meet this requirement. C-PVC is the preferred piping used in fire suppression systems in commercial, industrial, and residential buildings.

“CPVC compound when formed into pipe and fittings...exhibited a flame-spread index (FSI) of less than 25 and a smoke developed index (SDI) less than 50, satisfying the requirements for installation in plenums spaces or within ducts in accordance with UMC and IMC Sections 602.2” (3)

For comparison “PVC has low flame spread, but smoke developed ratings may be as high as 900, so PVC will not pass the 25/50 criteria of the ASTM E 84 test and may not be installed in plenum spaces.” (4)

This is an example of how making the assumption that C-PVC and PVC piping can be treated as the same application can be dangerous. When designing your system you must treat C-PVC uniquely to avoid compromising the longevity of the system or causing a catastrophic failure!

C-PVC manufacturers list chemicals, and materials that are incompatible with C-PVC. Among those are rubber and flexible plastic materials which contain plasticizers due to the chemical reaction. These plasticizers cause a chemical reaction that breaks down the C-PVC molecule. (5)

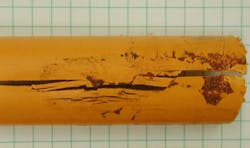

The unique chemical reaction between C-PVC and elastomers containing plasticizers cause the C-PVC product to discolor, suffer from softening, and expedited environmental stress cracking (ESC) making the piping becoming prone to fracture. There is no actual impact to the elastomer element, but only the C-PVC thermoplastic resin in contact with the elastomer.

Plasticizers are added to elastomers and plastics to promote plasticity, flexibility, and reduce brittleness. Plasticizers are added in the compounding of elastomers to improve workability, and assist with additives that are mixed into the material. Elastomers that are in contact with C-PVC piping leach plasticizers into the C-PVC resin. In high temperature applications this process between the plasticizers and the elastomer will be accelerated. (6)(7)

End-users of C-PVC systems must be aware of the importance of selecting compatible components for use in their systems. Compatibility does not stop with media which is running on the inside of the pipe, as these external couplings can also lead to piping failure

“Solvents or plasticizers may also be absorbed from the environment external to the piping system. Gasketing materials, caulks, rubber padding or lining materials may all contain plasticizers that can migrate into the rigid vinyl over time, leading to softening and eventual rupture under pressure.” (Knight)

Manufacturers do publish all of these compatibility concerns, and the manufacturer Lubrizol offers the FBC™ System Compatible Program online to identify problem materials as well as highlight their recommended materials. Lubrizol was the original company to commercialize C-PVC piping in the late 1950s. The goal of Lubrizol’s online compatibility program is “Eliminate the guesswork associated with chemical compatibility.” (8)

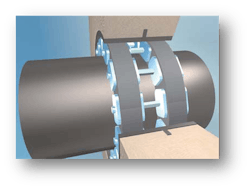

These compatibility issues remain when sealing C-PVC pipe penetrations through walls, floors, and ceilings. The design requires a modular seal which does not contain plasticizers to avoid creating a potential weak point in the piping system. The Model C-PVC Link-Seal® is made from a silicone compound that does not contain plasticizers in the formula, while the molded EPDM and Nitrile links will contain plasticizers. Sealing C-PVC pipe penetrations with EPDM or Nitrile links the C-PVC piping will cause Environmental Stress Cracking (ESC) and degradation of the piping to occur more rapidly.

John Stephenson is a Product Manager for GPT Industries.

References:

1.) Chemical resistance and chemical applications for CPVC pipe and fittings. Michelle Knight

https://www.nrc.gov/docs/ML1820/ML18207A604.pdf

2.) Harvel® CPVC Fire Sprinkler Piping Products – Caution Areas – Chemical Compatibility

https://www.cfm.va.gov/til/dManual/ChemicalCompatibility.pdf

3.) https://www.flowguardgold.com/plenum-ratings-for-flowguard-gold

4.) https://www.charlottepipe.com/Documents/InTheNews/CPF_Value_Engineering_Brochure_R2.pdf

5.) https://code-authorities.ul.com/about/blog/products-used-in-air-handling-spaces/

6.) https://plasticpipe.org/building-construction/bcd-cpvc.html

7.) https://www.pmengineer.com/articles/84632-plastic-pipe-and-fire-safety

8.) https://www.flowguard.com/blog/why-cpvc-pipe-fails-and-why-it-succeeds