Water Quality Sampling and Analysis to Optimize Water Heater System Performance

- Overlooking water quality can lead to costly inefficiencies

- Proper water quality assessment requires detailed analysis

- Water testing and analysis need to be done on a regular basis

- Targeted strategies may involve water treatment and/or conditioning solutions

In real-world conditions, water carries a wide array of minerals, chemical compounds, gases, suspended particles, and microorganisms. These largely invisible elements can profoundly impact the performance, lifespan, and safety of commercial water heating systems. Overlooking water quality can lead to costly inefficiencies, safety concerns, and premature equipment failure. For these reasons, a proactive approach to managing the water quality is essential for building performance and occupant safety.

Water Quality Defined

When we talk about water quality in relation to commercial water heaters, we are not concerned with how “clean” the water looks, tastes, or smells. Water that is perfectly safe for drinking or showering may still cause significant damage in a heating system.

For commercial water heaters, water quality refers to the chemical, physical, and biological characteristics that determine how water behaves under heat and pressure. These traits influence whether water heaters will suffer from scaling, corrosion, fouling, or bacterial growth—all of which can compromise system performance and longevity.

The source and environment of the water supply also matter. Variations in dissolved substances pose different risks, based on regional geology, plumbing infrastructure, or even seasonal shifts.

Proper water quality assessment requires detailed analysis of chemical composition, biological content, and physical properties. By understanding the water characteristics in heating systems, the right treatment strategies can be implemented to protect equipment and ensure consistent, efficient performance.

Water Quality Matters

Water quality is crucial to the health and safety of building occupants, as well as the longevity of equipment. Here are four reasons why maintaining proper water quality is important.

1. Health and Safety: Contaminated water systems can harbor harmful bacteria, such as Legionella. High chloride levels have also been linked to long-term health risks, including elevated blood pressure. Ensuring high water quality is, therefore, essential—not only for safe water heater operation but also for maintaining a healthy environment for occupants.

2. Equipment Longevity: Monitoring water quality helps protect water heaters from scale, corrosion, and microbial growth. Scale acts as an insulator, reducing heat transfer efficiency and causing heating elements and heat exchangers to work harder. This can increase energy consumption, reduce equipment lifespan, and lead to higher maintenance costs. High chloride levels and imbalanced pH can cause corrosion, damaging tanks and pipes, voiding warranties, and causing unexpected downtime.

3. Higher Efficiency: Water heaters free from scale and corrosion are more efficiently—some systems reach up to 99% efficiency (figure 1). Maintaining high water quality improves system performance, reduces energy consumption, and lowers operational costs.

4. Environmental and Sustainability Goals: Water heaters that run more efficiently, last longer, and require fewer repairs help meet corporate sustainability initiatives. Ensuring optimal water quality can reduce energy consumption for a more environmentally-friendly operation.

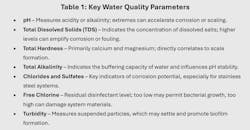

Key Water Quality Parameters

When evaluating water for heating systems, several core parameters provide critical insight into immediate and long-term risks. Understanding these values helps determine whether water is likely to cause problems and what mitigation strategies may be needed. Table 1 lists critical parameters.

Collecting and Analyzing Water Samples

To ensure hot water system operate efficiently and have long lives, water testing and analysis need to be done on a regular basis. Three options are available:

- Third-Party Laboratory Testing: Specialized labs have the equipment and expertise to test for a wide range of contaminants and provide water quality reports. Many, however, don’t interpret the results or provide recommendations for remediation.

- On-Site Testing: Some water quality parameters—including pH, hardness, and chlorine levels—can be evaluated directly on-site using portable testing kits. Not all elements can be effectively tested in-house, however.

- Manufacturer Analysis: Certain water heater manufacturers provide testing services for customers. By sending a water sample to the manufacturer, facility management can receive recommendations on the best treatment methods for their specific situation. Plus, manufacturers will often offer water quality courses to establish proper procedures.

Treatment and Conditioning Solutions

If water testing reveals issues, targeted strategies may involve water treatment and/or conditioning solutions (figure 2) to help ensure the performance and longevity of water heating systems and protect building occupant health. Choosing the right treatment approach depends on the full water quality profile and system requirements, ensuring reliable, efficient operation over the long term. Among the most common are:

Water Softeners – These systems are effective for preventing scale by exchanging calcium and magnesium for sodium or potassium.

Media Assisted Crystallization (MAC) – A chemical-free method that converts hardness minerals into inert crystals. This salt-free alternative prevents scale without removing beneficial minerals or requiring backwashing.

Filtration – Essential systems to remove particulates and turbidity that can clog components or support bacterial growth.

Reverse Osmosis (RO) – A useful option for limiting high TDS and corrosive ions, though post-treatment may be needed to stabilize the water.

UV Disinfection or Controlled Chlorine – An alternative for systems vulnerable to microbial contamination, they can mitigate risks from pathogens like Legionella.

Chemical Additives – Corrosion inhibitors, pH stabilizers, and other chemical additives help fine-tune water chemistry.

Conclusion

A proactive approach to water quality is becoming a core element to maintain mechanical system health. Incorporating regular water testing into a system maintenance strategy, interpreting results holistically, and acting proactively with targeted treatment, will help avoid costly repairs, improve system energy efficiency, and assure building occupant health.

About the Author

Armin Madani

Armin Madani, a civil and environmental engineer, is a Certified Water Treatment Designer (Water Quality Association) and certified by the American Society of Sanitary Engineering in Legionella safety. He has managed a portfolio of commercial water quality systems at Lync by Watts for the past four years.