Latest from Management

Sponsored

Many mechanical contractors are moving more work to the shop because it makes sense. It is safer, delivers better quality, and is an answer to address the shortage of skilled field craftsman. As cited in the May issue of Contractor Magazine, some contractors are co-locating shops for piping, plumbing, heavy metal, and sheet metal to focus more on work in the shop. While many mechanical contractors have always located these shops in the same general area, the difference now is that the shops are combining their outputs into manufactured modules, panels and racks. Some contractors are including electrical and fire protection components in the modules they build.

This is a great productivity improvement to do more manufacturing type work in the shop instead of the field. However, there is more productivity to be gained. Lean is coming on strong in the field construction to increase productivity. It is even more applicable in the shop. Lean actually started in manufacturing. It has many more tools for improving the shop environment than on the job site.

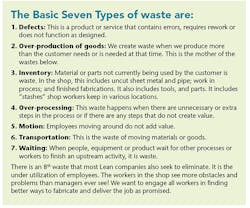

Lean’s purpose is to add value and drive out waste. Your shop exists to serve your customers, not to produce lots of pipe. All fabrication plans and processes should be aimed to help deliver better value to your customer. Value is a useful (quality) product with the least amount of cost (price paid, time and hassle). There are seven basic wastes we want to eliminate. [See side bar.]

Your competition can and usually does buys the same pipe, equipment and computer systems as you. Your competitive advantage comes from the your skilled employees and the way you manage your processes. All work is a process, master your process and you beat your competition.

Instead of turning out lots of product in batch format trying to create greater shop efficiency,; Lean seeks to match our fabrication schedule to meet the installation rate of the customer (our internal installation crews or external contractors). This may mean less efficient operation of equipment in the shop. Producing too much product or too soon, A.K.A. overproduction, is a waste we want to attack.

An important Lean shop principle is “Flow.” Once we start fabricating metal, we want the product to flow through the fabrication steps to the assembly area and then out to our customer. This idea is especially important for building modules in combined shops. We don’t want any shop to push product out the door and then have it wait for the other shops to deliver their components.

Inventory is waste, though some inventory of parts and material is a necessary evil. We want to keep just enough inventory on-hand so the work flows. We want to avoid excess inventory that has to be stored, protected, counted and constantly moved.

An important Lean principle is to “Go and See.” Go watch the fabrication and assembly processes several times. Often, tools used in the work are poorly located, and much treasure hunting eats up the worker’s time.

Lean especially focuses on managing and reducing the hand-offs between the value-added operations in the fabrication and assemble processes. Typically only about 3% of all the work done in a process is value-added. Some of the other steps are non value-added and just not necessary. Stop that right away. However, much of the work done in fabrication is not value-added but is “sort of” necessary.

I say, “sort of” because who says it is necessary? The laws of physics (moving pipe from A to B), governmental laws (OSHA or EPA), and customer requirements are necessary. The rest of these non value-added steps are done because we as management say they are necessary. If management makes the rules, management can change the rules. All it takes is for shop leaders to understand the process, observe it in action and question why.

A key Lean technique applicable to the shop is the 5S's. It came from Toyota (manufacturing) and is used to organize and visually control the workplace to eliminate waste. The 5S's are:

· Sorting out the necessary from the unnecessary. Most shops have material stored, stacked and cluttered everywhere. If you haven’t used something in a year and have no known plans to use it – get rid of it. It takes up space and makes for a disorganized work area.

· Simplifying. What we determine we need to keep should to be organized in a way so everything has a place and is near the point of use.

· Sweeping: We want to keep the workplace clean and also visually sweep the shop to put back tools and parts not in use. This especially reduces treasure hunting.

· Standardizing: We want to use the same color codes, organization methods and equipment in all shops.

· Self-Discipline or Sustain: We need to maintain the gain made by the 5S’s. Otherwise the shop will soon return to its evil disorganized and cluttered ways.

It is beyond the scope of this article to instruct in all the Lean techniques applicable to the shop. There are many that can pay real dividends when applied correctly and information on all of these is readily available online. A few key ones include:

· Kanban

· Muda Walks

· Pace

· Poke Yoke

· Spaghetti charts

· Takt Time

· Value Stream analysis

· Visual Management

Study these tools and apply them in the shop to gain greater productivity.

Dennis Sowards is an industry consultant and guest writer for Contractor Magazine. His company is Quality Support Services, Inc. He is the author of The Lean Construction Pocket Guide that has sold over 7,000 copies. He can be reached at [email protected] or at 480/835-6048.