Combustion Control: Safety and Design Features

Combustion equipment safety is essential for the daily operation of facilities and safety of plant personnel. Safety protocols and mechanisms in industrial plants have improved drastically in the last century, but incidents still occur far too frequently. Because boiler systems are inherently dangerous, safety must be factored into the design of not just the boiler but also the burner, combustion control, and overall operation of the system. This article examines the features and options typical of combustion control systems (CCS) today.

Combustion Control Systems

Depending upon the complexity of the boiler, the CCS can also provide other functions, such as drum level control and draft control. With low-NOx burners, it also controls the proper amount of flue gas recirculation (FGR) to the burner. For the sake of simplicity, the various types of CCS described below will be for boilers firing a single-fuel, gas-only system, as fuel-oil and sol- id-fuel systems add an entirely new level of complexity.

Single Point Positioning Systems

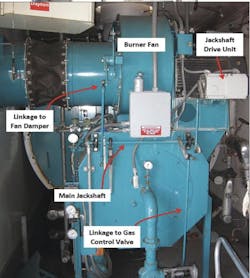

Single point positioning systems, also known as jackshaft systems, are often the least expensive options and are commonly found on smaller or older boilers. The fuel control valve and combustion air damper are mechanically linked together and controlled by a single actuator. This necessitates that these components are in relatively close proximity to each other.

A single-loop, or electromechanical, controller senses steam drum pressure and sends a signal to the actuator to control the firing rate of the burner to meet the required load demand. A common jackshaft with multiple crank arms then rotates and positions the fuel control valve(s) and air damper(s)/burner register louvers. The fuel valve typically has a characterizing cam that allows you to set the AFR over the firing range of the burner. This system is failsafe. In the event of a failure of the actuator, the burner will remain in the proper AFR but will freeze at that exact firing rate.

A major drawback to the single point positioning system is that the amount of hysteresis that exists in the linkage requires the AFR be setup with additional excess air to overcome this “slop” and keep the burner from entering a dangerously rich condition. This is also amplified by the lack of repeatability of the fuel control valve and combustion air damper positions during increasing and decreasing firing rates. As a result, the burner can never be tuned to its maximum efficiency, as excess air always has to be added for safety.

In addition, single point positioning systems will also require periodic retuning to compensate for the varying combustion air temperatures during the year, so it is common to retune for the summer and then again for the winter months. Due to the mechanical nature of the linkage, these systems are also prone to mechanical wear.

Parallel Positioning Systems

Parallel positioning systems, or “linkage-less” systems, are the most common systems found on newer firetube and smaller watertube boilers. These systems eliminate most of the linkage hysteresis problems found with jackshaft systems and allow the burner to be tuned with less excess air and therefore operate more efficiently. They also have the advantage of being able to mount the actuators and valves in a more convenient location that makes for a much less cluttered and more serviceable burner front. This level of control is also required for most low-NOx burners.

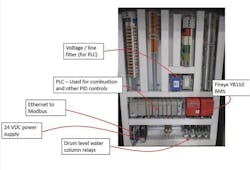

Linkage-less systems are provided in one of two ways: as a packaged microprocessor-based system that integrates both the BMS and the CCS or as a programmable logic controller (PLC)-based system. They provide a separate servo or actuator for the fuel control valve, combustion air damper, and FGR control valves.

Ideally, the actuators are direct-coupled to either the control valve or damper, thus eliminating any linkage issues. Air/ fuel curves are set digitally in the CCS through either a local human-machine interface (HMI) touchscreen or laptop computer.

The CCS is responsible for keeping the air and fuel actuators in the proper synchrony and position during load swings to maintain the programmed AFR. This is accomplished by what is commonly called “cross-limiting” through position feedback signals from the actuators to the CCS to ensure the burner maintains the proper AFR in the event of actuator failure. Since this system relies on consistent and repeatable fuel valve and air damper positions to maintain the AFR, the pressures must also be consistent and repeatable at the inlet of the fuel control valve and air dampers.

The control signals to the actuators can be either analog (typically 4-20 mAdc), digital (typically Modbus), or a combination of both. Digital control offers the advantage of less wiring since the control and position feedback signals are combined in a single, twisted pair cable that is daisy-chained to each actuator.

Features available for systems that utilize parallel positioning include oxygen trim, variable frequency drives (VFDs), and PLC-based controls. The architecture of these systems typically allows for additional burner efficiency improvements that can be provided with flue gas oxygen trim and VFD combustion fan motor control. Oxygen trim systems add efficiency by correcting for combustion air density and minor Btu variances with the fuel gas that have changed from the initial burner tuning. The combustion air damper is trimmed by up to +/-10% to adjust for these changing conditions. The CCS is programmed to maintain the varying optimal flue gas oxygen levels that were determined at each test point during the initial burner tuning. With oxygen trim systems, it’s important to budget for test gases to periodically calibrate the oxygen analyzer, and it’s recommended to check calibration at least monthly.

VFDs offer the potential for electrical power savings from the combustion blower motor. A VFD works in the following manner:

- Instead of moving combustion air dampers to control flow, the speed of the fan wheel controls the flow

- A speed reference signal is sent from the CCS to the VFD changing the electrical frequency that powers the motor, and a frequency feedback signal from the VFD to the CCS provides the required cross limit data

The rated motor RPM is typically found at 60 Hz, and, as the frequency decreases, so does the motor speed. There is a linear relationship on fan speed to flow, but it is a square root function on the static pressure. If the fan speed is set too low, the reduced static pressure can affect the ability of the burner to properly mix fuel and air, which can result in high carbon monoxide levels.

There are also minimum frequency limits on the motor that pertain to motor cooling. As a result, in most cases, the combustion air damper actuator is still required to control airflow at the lower firing settings. The electrical savings is realized by the significantly less motor horsepower required at low fan speeds.

PLC-based systems allow the flexibility to provide other energy-saving schemes, such as combustion air temperature compensation. Temperature correction for combustion air is especially important on the West Coast, where ambient temperatures from morning to afternoon can easily swing 30°F or more. For the cost of a temperature sensor, temperature correction offers the most bang for the buck in terms of fuel savings.

Be careful, as there are many older parallel positioning systems that still exist that do not incorporate any of the safety feedback features of today’s systems. These systems simply operate the fuel and air actuators with a common signal and do not have any cross-limiting that guards against air/ fuel imbalances associated with an actuator failure. They are inherently unsafe and should be replaced with a more modern system.

Fully Metered Systems

Fully metered cross-limited systems are typically the most efficient and expensive method for combustion control. Due to the high initial cost, these systems are typically found on larger watertube boilers in excess of 60,000 pounds per hour, where the potential for fuel savings makes it cost-effective. Furthermore, they are typically PLC- or DCS-based due to the complexity of this system.

This method utilizes mass-flow transmitters that are typically pressure- and temperature-compensated to measure the fuel and combustion airflows to provide a precise AFR for the burner. The control scheme is similar to the parallel positioning system as described above, except the flow signals provide the primary feedback to the system. The position feedback signals from the actuators are used in the error-checking logic that guards against flow transmitter and actuator failures. The AFR is also configured so that on increasing loads the combustion airflow leads the fuel flow, and, conversely, on decreasing loads, the fuel leads the air.

Many ultra-low-NOx burners will require what is described as a “double cross-limited” system, which requires a very tight control of the AFR during load swings. This results in a very slow response to load changes, taking several minutes to go from low fire to high fire.

Draft Control

Draft or furnace pressure control systems are required when the boiler has an induced draft fan, a tall stack (typically greater than 60 feet), or a common stack for multiple boilers. Typically, an actuated breaching damper on the boiler is modulated to hold a constant pressure in the furnace.

With a PLC- or DCS-based system, the draft control can be enhanced by adding a feed-forward scheme in conjunction with pressure control to anticipate changing loads to start opening or closing the breaching damper. Maintaining consistent furnace pressure helps to maintain the proper burner AFR.

Drum Level Control

Proper feedwater level control in the steam drum is critical for both the safety and operation of the boiler. If the water level is too high, the water carryover in the steam line can damage equipment in the plant. If the water level is too low, the boiler itself can be severely damaged. To complicate things, as the steam drum experiences a drop in pressure from a sudden increased load, the drum level will swell due to the decreased density of the water. Conversely, on a rapid decreased load, the water level will shrink.

The steam drum level is typically controlled via a feedwater control valve. There are several ways to control this valve: single element control, two element control, and three element control.

Single element control, which is the most common method, utilizes a level transmitter on the steam drum to open and close the feed- water valve to maintain the proper level. Various instrument technologies exist today to measure this level; the most common is pressure differential. Single element systems work well on boilers that have very slow load swings. On rapidly changing loads, more sophisticated methods are required to compensate for the shrink and swell phenomenon.

Two element control adds a steam flow feed-forward signal to the drum level equation to anticipate the need for more or less feedwater based on steam flow. As the boiler produces more steam, it will obviously require more feedwater; the opposite is true as the steam flow decreases. This approach works well for steam plants that only occasionally experience sudden load swings.

For steam plants that have batch steam loads or experience frequent sudden load swings, three element control becomes necessary. In this method, steam flow, feedwater flow, and drum level are all included in the feedwater control equation.

In a perfect world, as a pound of steam is released from the boiler, a pound of feedwater must be replaced into the boiler; however, blowdown losses and accuracy/repeatability/ turndown issues with flow and level transmitters come into play. The drum level component of the control scheme is used as a trimming mechanism to compensate for these issues. The control scheme is also limited by the turndown accuracies of the steam and feedwater instruments. In general, anything below a 20% load requires an automatic return to single element (drum level only) control.

Correct Configuration Can Make the Difference

Ensuring a CCS is configured correctly for each unique application can make a world of a difference in the overall efficiency and safety of the system. And with the advances in control technology today, there are many opportunities to increase operating efficiency and improve overall safety through combustion control upgrades that are much more cost-effective today than they were just a couple of years ago.

About the Author

Jack Valentine

Jack Valentine is general manager of Nationwide Control Solutions – a division of Nationwide Boiler Inc.