Latest from Hydronics

Sponsored

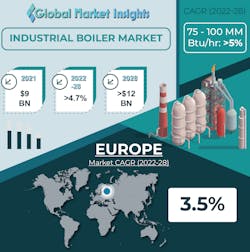

With the escalating developments across the manufacturing sector, the deployment of industrial boilers for producing steam and heat, generating electricity, and other industrial applications is anticipated to rise.

In developing nations, government entities are also planning to invest substantially in powerplants to generate clean electricity, asserting a positive influence on industrial boiler market development. To cite an instance, in March 2022, TANGEDCO (Tamil Nadu Generation and Distribution Corporation) unveiled its plan to install 20,000-MW solar power plants at around $9.1 billion by 2030.

Despite the necessity of steam generation, meeting emission standards have become a major concern for industrial boiler brands globally. Situations like these are leading to an increased reliance on efficient boiler systems for myriad industrial applications such as refineries, with three examples given below:

1. Brazilian Refineries

Technological developments and innovations are the main enablers of the carbon-free refinery and other processes. Due to the rising commitment of oil refineries to carbon neutrality, industrial boiler installation has been surging commendably in recent years.

For example, in March 2022, Hydro Alunorte deployed an electric industrial boiler, with modern tech and greater capacity, at its Alunorte alumina refinery located in Brazil as a part of its commitment to reach the carbon-neutral target by 2050. This electric boiler could cut carbon emissions by over 100,000 tons per year. In addition, the company was targeting to add two more electric boilers, which are expected to start operating in 2024, thus assisting the refinery industry in curbing emissions and environmental impacts.

2. Belgian Chemical Production

Efficient steam boilers are gaining immense popularity for use in processing plants across prominent industries including chemicals. Since chemical plays an integral role in economic advancement, businesses in the sector are adopting industrial boiler systems for energy-efficient operations.

Citing an instance, in March 2022, chemical company Vynova Group inaugurated a state-of-the-art hydrogen-based steam boiler system at its site in Belgium. By the end of the year, the company is intending to install a second, identical steam boiler, which could reduce carbon dioxide emissions of its Tessenderlo base chemicals production site by 10,000 tons each year, thereby strengthening the industrial boiler industry for steam generation applications.

3. Chemical Recovery in India

In the paper industry, steam is pivotal for the process of cooking wood chips in the digesters, meeting energy requirements, and drying papers. The robust demand for papers, especially in emerging nations, is therefore slated to generate growth opportunities for industrial boiler manufacturers. According to the IPMA (Indian Paper Manufacturers Association), per-capita paper consumption is around 13 kg in India. Furthermore, the installation of boilers across paper mills in the country has increased considerably.

For instance, in October 2021, ANDRITZ successfully started up a 550 t/d HERB boiler for chemical recovery at Naini Papers Ltd. in India. This boiler was designed to handle a mix of hardwood as well as agro-based black liquor. It can also enable environment-friendly and energy-efficient operations as compared to black liquor incinerators, while substantially increasing pulp production and power-to-heat ratio. This increasing dependence on boilers by paper brands could enhance the progress of the overall industrial boiler market in the years ahead.