Latest from Hydronics

Sponsored

2021 is a milestone year for me. This year I will have been in plumbing and hydronics for 50 years. My first job in the industry came in 1971 working for a plumbing and heating company that concentrated on very large multi-housing apartment units. This industry has provided an amazing living for my family and has allowed me to meet some really smart, knowledgeable tradespeople and contractors all over the United States who have become lifelong friends.

Over these five decades, I was the vice president of a plumbing and heating supply house for 20 years where I traveled over much of the U.S. doing classes on steam and hydronics. I also taught the State of Minnesota Boilers License training for 15 years, and for these last 12 years, I’ve been the customer trainer at Uponor. The best part of the whole journey is the amazing people I have met who make this the best place on earth to live.

In addition to all that, I have some pretty amazing stories! Learning doesn’t come without mistakes, and I’ve made a few really good ones. Remind me to tell you the sewer machine story someday. I nearly took apart a whole apartment with a sewer machine once. It was awesome. I bet that lady is still having nightmares. Boy, could she scream.

I am also getting older, and as long as I’ve been doing this, I am constantly amazed there are pieces of equipment used today that are older than me and are still not understood very well or used to their optimum potential. You’d think by now we would have figured all this stuff out. But, we haven’t.

So today, I’d like to talk about just one of these truly amazing devices that you may already be using and aren’t even aware of it or using it to its full capacity. I’m talking about the venerable reset ratio control (also called the outdoor reset control or boiler reset control or whatever name you use for it in your neck of the woods).

Reset controls are by no means new. The Honeywell T475 outdoor reset control has been around longer than I have, and they are still controlling the boiler water temperature in hundreds of thousands of boilers in North America alone. And today’s reset controls have capabilities that will make your hydronic system send you a thank you card.

So, what is a reset control and what does it do? Or even better, what’s it capable of doing? In its simplest form, it raises and lowers the boiler water temperature based on the outdoor temperature. The colder it gets outside, the warmer it makes the boiler water. Conversely, the warmer it gets outside, the cooler it makes the boiler water. Simple, huh?

You’re probably thinking, “So, if I set my thermostat at 72 degrees, and it stays at 72 degrees no matter what the outside temperature is, why does it matter?” Well, I’ll show you.

Boilers are sized based on what is called “outdoor design temperature.” Outdoor design temperature varies depending on where you live. It’s the outdoor temperature that your part of the world is at or above 99.6 percent of the time. To put it more simply, “How cold does it get where you live?” Here in Minneapolis, the outdoor design temperature is -14.9°F, which should immediately trigger the question, “Why does anyone live up there?”

It can, and does, get colder than that. However, it is assumed that it will be for a short time, and the thermal mass of the house will carry you through. That’s why you don’t size a boiler for the absolute coldest day it can ever get. Otherwise, every boiler north of the Mason-Dixon Line would be way oversized.

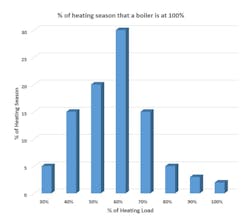

Below is a chart that comes from ASHRAE. It shows the percentage of time for the heating season and what percentage of those times the boiler is running at 100%.

You can see from the chart that the boiler is only operating at full capacity 2% of the time. The other 98% of the time, the boiler is oversized. As a matter of fact, for 30% of the entire season, the boiler is running at 60% of its capability. To keep it set at its highest water temperature setting would cause it to short cycle more than half of the entire heating season, especially the shoulder seasons of spring and fall. It may need 180°F water for a few days in January, but it certainly doesn’t need that when it’s 40°F outside. The boiler will sit and short cycle every time it gets a call for heat (non-modulating boilers only).

Modulating condensing boilers can do another trick where they modulate the flame size based on the supply water temperature and the return water temperature. It’s kind of like when you step on the gas to get your car moving. Initially, you press your foot down with intensity when the light turns green to get the car going. But, when you get to your desired speed, you let up a little bit. You “modulate.” See what I mean? Coupled with a reset control, you can dial in a really efficient system.

And so, we put a reset control on the boiler to raise and lower the supply water temperature based on the outside temperature. There are different kinds of reset controls. Some have a fixed reset ratio. In a 1:1 (pronounced one-to-one) reset ratio controller, for every 1°F the outside temperature drops, it raises the supply water temperature of the boiler 1°F. In a 1:2 reset ratio, for every 1°F the outside temperature drops, it raises the supply water temperature of the boiler 2°F. In a 2:1 reset ratio controller, for every 2°F the outside temperature drops, it raises the water temperature of the boiler 1°F. You need both kinds for very severe cold climates (1:2) and for milder climates (2:1). Additionally, there are digital versions that allow you to choose a multitude of reset ratios.

Now, here’s where it gets interesting. This is where we separate the comfort pros from the rest of the pack. There are also three different reset controls strategies. There is “full reset”, “partial reset”, and “load reset” (or “heat emitter reset”). The names of the three might change in different parts of North America, but it’s the same idea.

Full reset is where the reset control, usually mounted on the boiler, near the boiler, or in the boiler, resets the entire load temperature. All of the supply water temperature is controlled by this one reset control. Other mixing valves might be downstream, but the supply water temperature is the same. These are usually used for mod-con boilers and low-temperature heating systems, such as radiant. Their range could be anywhere from 180°F to 80°F, as an example. This works well on most modern houses built today.

Partial reset is used when you don’t want the supply water temperature to drop below a fixed temperature, such as 140°F. They will raise and lower the temperature anywhere from 200°F to 140°F. These are usually used for non-condensing boilers to prevent them from becoming condensing boilers.

And finally, there is load reset or heat emitter reset. This is where just a particular heat emitter, such as a single zone of a 10-zone radiant system, has its supply go up or down based on the outside temperature. This is for the comfort pros. Here’s how it is used.

Load reset is a type of mixing valve where the mixing device provides different water temperatures based on the outdoor temperature rather than just the return water temperature that other mixing valves use. The best part is, it’s not limited by the boiler manufacturer’s minimum recommended operating temperature. This ability provides much finer comfort settings by reducing indoor temperature swings and increases system efficiency by reducing system distribution losses because of higher heat, particularly in large, custom homes.

One of the great benefits of this reset is that it allows older, cast-iron, non-condensing boilers to fire to their high limit where you might have some high-temperature heat emitters and some low-temperature heat emitters all on the same system.

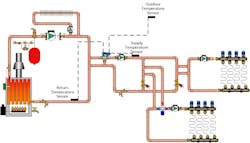

In this drawing, you have a high-temperature loop and two low-temperature loops. The load reset mixing valve provides the primary loop with high temperatures for baseboard and two individual low-temperature radiant loops, and the reset protects the boiler from going below 140°F to prevent it from condensing. With this design, the low temperature loops go up and down based on outdoor temperature. For older custom-home remodels, this is a great solution.

Most of these new digital controls have a warm weather shutdown (WWSD) temperature that cuts all heat off at a pre-set outside temperature, such as 60°F. Some even have unoccupied/occupied settings to change if there is no one in a room for a particular period of time. Isn’t that great?!

It’s important to remember that all of these reset controls do not take the place of limit controls. Reset controls are strictly operating controls. You must also have high-limit controls to protect the system from overheating, as well.

I hope this explanation helps you see a fresh picture of a very useful older product. Kind of like me!

I would be grateful to hear your thoughts, ideas, and stories. You can reach me at [email protected].

Until then, best regards, and happy heating.

Steve Swanson is the customer trainer at Uponor Academy in Apple Valley, Minnesota. He actively welcomes reader comments and questions at [email protected].

Steve Swanson

Steve Swanson is the customer trainer at Uponor Academy. He actively welcomes reader comments and can be reached at [email protected].