In a construction environment where adoption of advanced technology is still developing, one company has taken a decisive lead. HC Blake—a Huntsville, Alabama-based contractor—isn’t just embracing innovation, it is championing the use of advanced technology to general contractors and trades in Huntsville and its surrounding counties. HC Blake has been a trusted choice for plumbing, heating, cooling, and electrical contracting in northern Alabama since 1884.

Luke Batson and Bryant Fair, whose family has led HC Blake for six generations, make the point that technology simply makes sense for a modern construction company. Lately, Luke’s focus has been on virtual design and construction (VDC) software. Luke says, “We just see the benefit of adopting technology that lets us show anybody a drawing, regardless of their training, and have them understand the whole project more clearly. General contractors prefer working with HC Blake because we use Trimble MEP technologies.”

HC Blake is continually looking for new ways to deliver better results for customers whether they’re working on a commercial building, public facility, or private project. Today, that means leveraging modern software to streamline design and estimating workflows while facilitating greater collaboration between the office and field personnel.

Detailing with Trimble SysQue

HC Blake turned to Trimble MEP software for a straightforward, practical reason: to save time. The company’s detailers were spending hours each day modeling their work for prefabrication. Mark Campo, director of HC Blake’s VDC department knew he needed a way to streamline the work and improve productivity.

“If you’re spending 30 minutes per page in a prefab manager, that’s lost time that could otherwise be spent much more productively,” Mark points out. “We started looking at different software offerings and came across Trimble SysQue with its own library of MEP components, we would no longer have to import that information from all the different manufacturers. So that was a no-brainer for us.”

In fact, to streamline detailing and prefab workflows, HC Blake invested in a suite of integrated solutions that includes manufacturer-specific BIM content and fabrication software. The company also discovered another opportunity to save even more time by using the Trimble Connect collaboration tools that are also included in Trimble VDC Pro+.

Luke says, “We were spending a lot of time creating templates, but if we had a Revit viewer we wouldn’t even need them. Since we had Trimble Connect as part of Trimble VDC Pro+ we figured that was the way to go.”

Mark adds, “If we need a quick way to show the team in the field a building detail or how to correct a problem, they could just pull up the drawing and dimensions on a tablet or smartphone using Trimble Connect. The efficiency we saw from that capability pushed us to start using Connect.”

With a fully integrated workflow between the software and manufacturer-specific MEP content, field personnel have access to constructible models from the jobsite. This enables them to build confidently from the coordinated model with visibility to real-world dimensions of building materials.

Collaboration from Office to Jobsite

Construction-specific tools help detailers in the office communicate and collaborate more efficiently with field leaders. For example, detailers can visually monitor the progress of teams in the field and can easily track what work is completed, how long the work is taking, and any construction issues impacting progress. Mark also uploads model revisions to Trimble Connect for archiving and to manage version control, ensuring that stakeholders do not use outdated information.

“I can get ten or more dimension requests a day,” Mark says. “Now, I don’t need to print them out a dimension drawing, they can pull it themselves. Between handling phone calls, printing out the drawing, and having it driven out to the site, we’re easily saving one or two hours for each dimension request. Our field teams now have a lot more independence to view the dimensions they need whenever they need to.”

Mark adds that because of the accuracy of Trimble SysQue, he can share the model using Trimble Connect with confidence and avoid sending the entire Revit file.

“I prefer not to send out the whole Revit file because I don’t want them to change anything,” Mark notes. “Plus, a Revit file is so large, that would be another 30 minutes taken out of my day just to get it prepared and emailed. Trimble Connect is so quick, I don’t have to send the Revit file into the field and worry that they’re going to change something.

Improving Efficiency, Accuracy

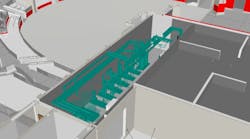

HC Blake has also improved the efficiency for its field teams and avoids costly mistakes. For example, the company recently completed a project for an amphitheater, which presented unique challenges as a radial structure. Due to its curved design, the standard way of dimensioning would not work. However, Trimble Connect includes capabilities to produce accurate dimensions even for non-square, non-perpendicular buildings.

“We could determine the closest dimension between one item face and another, which had a major impact on the field team’s ability to stay productive without taking time to run a lot of complicated calculations. The building didn’t even have a constant radius; it was more like an oval, but we were able to dimension it without a problem.”

Luke adds, “Just being able to visually share what the building looks like before it is built helps us save time and improve efficiency. We don’t have to train people to read the drawings. They can see how the systems should be constructed. If there’s a mistake, we can spot that a lot faster in a 3D model than on a 2D drawing and correct it in the software instead of wasting time and resources in the field to reposition a pipe or duct run.”

Data-Driven Project Planning

Additionally, the team at HC Blake can provide a paper trail of the entire design history. For example, they can review the as-built design compared to earlier versions and use the design records as documentation for project closeout.

Luke also appreciates the Status Sharing feature in Trimble Connect, which enables him to leverage data from Trimble Connect to track the completion of work throughout the project. “Using Status Sharing, we’re able to better understand how long certain tasks take in the field, which allows for more accurate project bidding and planning in the future.”

Because Trimble Connect is also included in Trimble AutoBid Estimating Essentials, it provides a connection point to other functions in the company such as estimating. For example, the team can refine estimates using the knowledge gained from Trimble Connect to ensure bids are accurate and profitable. “That helps give HC Blake a little more advantage in competitive situations,” Luke adds.

Simplifying the MEP Learning Curve

Beyond its use as a valuable collaboration solution, Trimble Connect helps HC Blake onboard new hires more quickly. They can use the 3D model as a teaching tool, even for people with little-to-no experience in the trades or with technology.

Luke explains, “We have always hired people not just based on what they know, but more for how hard they work. We provide the training they need, and in the past that meant being a helper for two-plus years. Now, using the modeling and Trimble Connect, they're able to understand the MEP systems within about six months.”

As HC Blake continues to roll out all the tools included in VDC Pro+ and AutoBid Estimating Essentials, Luke and Mark are confident people will adopt the additional capabilities quickly and effectively.

Mark says, “I like how all the software talks to each other. Having a single, integrated platform to learn will be very beneficial for us as we fully implement more capabilities across the company.”

Luke concludes, “By adopting these solutions and other advanced technologies, HC Blake is demonstrating to our customers and general contractors the value of embracing innovation. Technology is helping all our departments to work more collaboratively together, and ultimately that’s enabling us to deliver more responsive, quality service to our customers.”