AHR 2017 in Las Vegas — what a show! More than 2,000 HVAC exhibitors and 60,000+ people attending from 150 countries, all speaking HVAC.

It doesn’t get any better than this! And with education classes on almost every conceivable aspect of our industry from some of the industry’s leading experts, you could walk away with a mountain of information and skills you couldn’t get anywhere else.

After two days of roaming the two-million-square-foot exhibition space, I felt like my six-inch mind was trying to fit around a seven-inch idea. To grossly understate it, there are some very clever people in this industry.

I suppose this year’s attendees could have a different idea of what they saw as industry “trends,” based on their interests and business types. What I would like to do in this article is simply to share some thoughts about what I saw at the 2017 AHR Expo.

To narrow the field, I broke up the expo floor into four types of exhibits or products. The first three types are the three major ways to transport energy from one place to another: air, refrigerants and water. The fourth type of exhibit would encompass all miscellaneous support products, such as tools, chemicals, software, indoor air quality products, etc. that are connected to the other three. Each of these categories could be an article by itself, so I had to find a way to narrow the topics down.

Since the energy-transport capabilities of water are 3,500 times greater than air and there is no safer and more environmentally friendly refrigerant than R-718 (water), for the purpose of this article, I will focus on what is trending in water distribution.

Let me show you just one example. While walking around the show, I met Zeke Bochenek from Metraflex. Zeke was demonstrating his company’s new wye strainer. Now, wye strainers have been around for well over 100 years and they all look the same to me, so I was intrigued to see what his company had come up with that could possibly change the way a wye strainer works.

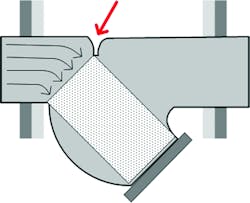

Zeke seemed pretty excited about his new wye strainer, so I thought I owed him a listen. This is where the clever part comes in. Figure 1 shows the inside design of a typical wye strainer. For more than 100 years, it has not changed much at all.

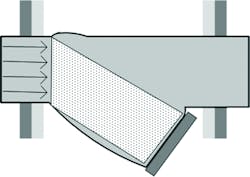

As you can see from the drawing, as the water hits the body casting bridge that diverts it into the screen to be filtered, the bridge creates quite a resistance to flow. Zeke’s company simply reengineering the body to remove the bridge (see Figure 2). This decreases the flow resistance, making the pump’s job easier. Isn’t that clever? It was another one of those, “Why didn’t I think of that?” moments. But when you do the math on the savings, you realize how much this small re-engineering project actually saves.

According to the company’s literature, a 2½-in. traditional wye strainer has a CV of 110. CV is what measures the performance of a valve or pipe or fitting. The higher the CV number, the better the performance (and more money it will save). The CV of this new strainer is 160. That is a 45% increase in performance.

So, suppose I have a 2½-in. line with 90 gallons per minute (GPM) moving at 6 feet per second using a 70 percent-efficient pump that runs all year long and costs $0.12 per kilowatt hour (kWh). Using this new product, I would save just over $100 per year in annual electricity costs…just from changing the wye strainer! Clever. This is why I like to attend AHR.

Which brings me to the first trend I noticed at AHR.

The mentality of “We’ve always done it this way” is being challenged from every direction. Putting fresh eyes on long-standing ways of doing things is the new norm. Dozens of times throughout the exhibition I saw products that had been around forever that had been reengineered to provide better performance and better quality. No longer can a product or procedure stand on the merits of just history alone. New perspectives are allowing fresh challenges to traditional standards of doing things.

This includes hot-water recirculation. I was talking to two old friends of mine, Rick Mayo and Dave Holdorf of Taco. (Just to make a distinction, there is a difference between “old friends” and “friends that are old.” These two fall into the first category.)

They showed me their new hot-water recirculation control called SmartPlug. You just plug the SmartPlug into an outlet and plug your recirculation pump into the SmartPlug. It’s that simple. But as soon as you plug it in, it begins to learn. It has a sensor that attaches to your hot-water supply pipe and it learns your daily hot-water usage patterns and adjusts the run time of the recirculating pump to save up to 94 percent of the energy that a recirculation pump would regularly use. Ingenious! It was such a good idea that it won the AHR Expo Innovation Awards Product of the Year. Congratulations, Taco!

Sophistication of controls is not a new trend, but it has definitely ramped up for 2017. On and off is being replaced by “variable” and “modulating.” Variable-speed pumps, variable run-time controls, variable-frequency drives, pulse width modulation, modulating burners, and on and on. Hardly anything just turns on and off. The only thing that seems to turn on and off anymore is my line of credit.

Another trend: Wired is being replaced by wireless. If you’re going to move forward in the HVAC industry, you better get a good grasp of IoT (Internet of Things). It’s the interconnectedness of buildings, electronics, sensors and smart devices that exist in the cloud. When I was a young man, the cloud was what you experienced when you walked into your apartment during poker night. Now it represents the homeland of all the information that runs your life. The good news is that this is where the millennials live. It’s a great time for them to show up.

Everything is changing. When I was a kid, the average family had two parents and four kids. Today, the average family has two kids and four parents. The dial is being replaced by the app. You can reset your thermostat from Bolivia. But you can’t watch TV if it’s raining. This makes the AHR Expo such a great place to step into the future and take a look around. The ironic thing about all of this is that today’s innovations often end up as tomorrow’s codes. It’s really important to keep up.

Problem-solving is reaching a new level

The trend of solving today’s issues with modern HVAC is a great reason to attend AHR. As all of us know, almost every advance in technology introduces a new set of problems. They introduced air bags into cars to save lives. Then the air bags themselves started to injure children sitting in the front seat, so they moved the kids to the back seat. But then the kids were being strangled by the seat belt, so they made the car seat face the other way. When the kids started to scream because they couldn’t see mom, and mom turns to comfort them — WHAM! — she runs into the car in front of her… and activates the air bag.

Technology is a fickle friend. But that’s where innovation comes in. One good example of this was from ADEY Professional Heating Solutions. Tom Tonkins and his very capable staff showed me a new product they have developed that really does solve a problem.

Since the advent of wet-rotor pumps, which are absolutely awesome in their ability to save energy and move water efficiently, they too, like almost all new technology, have developed another problem.

The magnetic field inside the wet rotor attracts the naturally occurring iron oxide in the water. This iron oxide, or magnetite, can impede the performance of the pump or possibly stop it. Chemicals help, but then you can have another set of problems.

As we all know, monitoring chemical levels lasts until the first budget cut, and the system is vulnerable again. Pump exercising certainly helps, but it cures the symptom and not the real problem. The best solution is to remove the iron oxide.

Along comes the Adey line of MagnaClean magnetic filters that do a spectacular job of removing iron oxide. It uses a very easy-to-install, slip-stream magnetic filtration device that attracts the iron oxide then traps it and flushes it away. Quickly and easily. And you don’t need a hazmat suit to do it. Watch a product demo done for Dave Yates when he visited the Adey booth.

This is what I’m talking about when mentioning the trends at AHR. You can see a terrific amount of problem-solving happening at a great show with a lot of education and information. If you have time, I would really like to hear your take on trends from AHR. You can reach me at [email protected].

Until then, best regards and happy heating.

Steve Swanson is the national trainer at Uponor Academy in Apple Valley, Minn. He actively welcomes reader comments and can be reached at [email protected].