To condense or not condense, that is the question

My eighth grade English teacher, Mrs. Lauer, defined a purist as “one who is preoccupied with the correctness of language.” I wrote it down because I realized then what I was — a purist. Words have meanings and they should be used correctly. So I rarely miss an opportunity to “mentor” someone who has mutilated a word meaning (this might explain why no one comes to visit me anymore).

Anyway, let me give you an example. Last summer I stopped at a fast-food restaurant to get a diet Coke. The nice young lady behind the counter asked with a pleasant smile, “How may I help you today?” I said, “I’d like a large diet Coke please.” She scanned the available icons on her computer screen and then with a furrowed brow replied back apologetically, “I’m sorry, we don’t have large. All we have is small and medium.”

This is where the purist in me came out. I had an opportunity for a real teaching moment. Not wanting to sound judgmental or condescending, I picked my next words carefully and replied, “Young lady, it is by definition impossible to have a medium without having both a small and a large. In order for it to be called a medium, it must have both of the other two — small and large. As you can see, without a large, you cannot have a medium; therefore, your medium is really a large, and I’ll have that.”

Then, I leaned back and waited patiently for her to realize the error of her ways. Her warm, pleasant smile ran away and was replaced by a completely blank stare. She gave me a look like I had just caught the last teleporter in from Neptune. And although I cannot say with certainty, I suspect that her finger was hovering just above the secret button under the counter that summons a SWAT team in the event some random nut-ball should happen to come into the store. (Yes, everyone knows they have a secret button.)

There was a tense pause. Sensing that the teaching moment was rapidly deteriorating, I said, “I’ll have a medium.” The smile returned and a once again pleasant voice said, “That will be $1.06. Have a nice day, sir!”

Sigh...

What is a condensing boiler?

I get the same purist reaction inside my head when I hear the words “condensing boiler.” It will generally start out as a friendly conversation about my favorite topic of hydronic heating. Invariably, the conversation will deteriorate into a verbal sparring match about which system is the best and then — and it always happens — someone will pull the pin on the grenade by saying, “The only boiler to use is a condensing boiler!” Boom! My mind explodes like someone tapping into the back bumper of a Ford Pinto. (Sometimes the explosion inside my mind is audible.) But rather than blurting out a lengthy stream of pithy expletives, it is always better to reason, so give me a moment to let the purist part of me rant.

In today’s market, there are two main types of natural-gas boilers. They are called “condensing boilers” and “non-condensing boilers.” Here’s the thing: all boilers, every single one of them, can and will condense if the conditions are right. The boiler could be named “Non-condensing Boiler” and be manufactured by the Non-condensing Boiler Manufacturing Company, and it will condense if the flue gas temperatures are correct. Let’s look at what is happening.

When you burn a fossil fuel like natural gas, it has some water vapor in the fuel. Under normal conditions, a therm of natural gas (100,000 BTUs) contains just slightly over one gallon of water vapor. Because it is a vapor, if we can get it to turn back into a liquid, we will release a significant number of BTUs trapped in the vapor as latent heat — a little over 10,000 BTUs, as a matter of fact. (Latent is a Latin word meaning “hidden.”)

The reason for this release has to do with a phrase in physics called latent heat of condensation. Every time a vapor condenses back into a liquid, it must give up 970.4 BTUs per pound of water as heat energy. Since a gallon of water weighs 8.33 pounds, and we are condensing slightly more than a gallon of water, a little over 10,000 BTUs of energy will be released back into the boiler system in the form of heat. This adds just about 10% more energy back. Just by condensing the flue gases!

One of the side effects of this condensation is that a small percentage of the water vapor (H2O) will combine with a couple of sulphur molecules that occur in all fossil fuels as sulphur dioxide (SO2) and become H2SO4 which is sulphuric acid. Very, very corrosive. The ability to operate and survive in this corrosive environment is one of the main things that differentiates a condensing boiler from a non-condensing boiler. A condensing boiler was made to survive this; a non-condensing boiler was not.

The same thing happens in an automobile that is only driven a mile or two to work. Because it never heats up over the dew point of the fuel gases, it is constantly condensing acid into the tailpipe and muffler and rotting them out. The car rarely achieves temperatures over the dew point, which would dry out the acids. Cars that drive a farther distance to work heat up enough to dry out the acid condensates and they don’t rot out the tailpipe and muffler. Cars that are driven a short distance to work typically replace mufflers and tailpipes several times during their lifetimes compared with cars that are driven a longer distance to work. Fortunately, catalytic converters do help this problem.

The key: return water temperature

In order to get a boiler to condense, we have to get the flue gas temperature reduced to the dew point of the flue gases. This is another thing that a condensing boiler does. On the inside, it has a heat exchanger to reduce the sensible temperature (or the measureable temperature) of the flue gases just like a non-condensing boiler. But it also has another heat exchanger that reduces the flue gases even further until it drops to the dew point and begins to condense. This part of the boiler is made of heavy stainless steel to take the acidic environment of condensing flue gases. The lower the return water temperature, the more condensate it removes, and the more heat it removes from the flue gases. Boilers will condense or not condense based on their return water temperature, not because it is called a condensing boiler or non-condensing boiler.

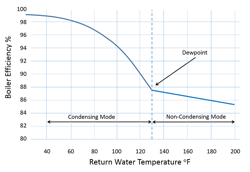

In short, any boiler can be a condensing boiler, and any boiler can be a non-condensing boiler, even though they are not made to be so. It is a matter of the return water temperature. Let’s look at the chart on this page.

This chart shows the condensing and the non-condensing modes of boilers based on their return water temperature.

- If the return water temperature is 90°F, it will be condensing and removing 95% of the heat from the fuel, whether it is a condensing boiler or a non-condensing boiler.

- If the return water temperature is 140°F, it will be a non-condensing boiler, even if it says “condensing boiler” right on the label. And it will be about 87% efficient, even if it says 97% efficient on the literature. Those efficiency numbers on a condensing boiler are based on an 80°F return water temperature and a 100°F temperature rise — certainly not the conditions I described.

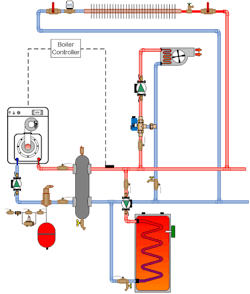

Let’s look at System 1 (see illustration). The system below is a condensing boiler with some baseboard heat and a fan coil unit. The baseboard was designed for this system to run at 180°F, with a return water temperature of 160°F. The fan coil was designed to run at 160°F, with a return water temperature of 140°F. So the lowest return water temperature of this system is 140°F. Using the chart above, at these design temperatures, it will never condense. Now, it may condense some in the spring and fall when the design temperature drops, but it won’t condense much. So you may have shelled out a lot of money for technology that probably won’t pay back very quickly.

SYSTEM 1

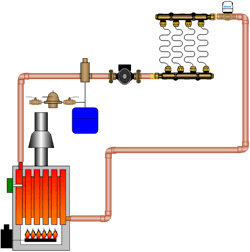

SYSTEM 2

In this system, the boiler is a non-condensing boiler with some under-slab radiant heating. The supply water temperature for radiant heating is 90°F with a return water temperature of 80°F. Using the chart above, with a return water temperature of 80°F, it will be condensing all of the time, even though this is a non-condensing boiler. The good news is the boiler will be very efficient for about six months. The bad news is it will be a rust pile on your mechanical room floor, because the acid has eaten it up like Pac-Man. This system could be modified to make some of these problems go away; but, in truth, a condensing boiler would have been a better choice.

My point is that there is not one boiler for all jobs, and you don’t choose a condensing boiler just because it is more efficient. You choose a condensing boiler because the predominant return water temperature is less than 135°F. Boilers need to be selected by the temperature of the return water. This will help your customer and you choose a boiler matched for the system that will provide years of trouble-free, comfortable heating.

Thanks for hearing out my rant.

I would be grateful to hear your thoughts, ideas and stories. Until then, best regards and happy heating.

Steve Swanson is the customer trainer at Uponor Academy. He actively welcomes reader comments and can be reached at [email protected].