Hydronic radiant wall heating, still the greatest trade secret in the U.S.

Every time I go across the Atlantic to visit a trade show on hydronic heating systems in Europe, I see more and more radiant systems designed for walls and ceilings.

I recently returned from the Mostra Convego Fiero (Comfort Show and Convention) in Milan, Italy, where I saw a continuation of what I have been seeing over the past 10 years. There were limitless displays of radiant wall heating/cooling and ceiling panels of every shape, design and size.

Every system manufacturer is offering dry panels and systems in a dazzling array of panel designs for ceilings and tubing mounting options for European style cement and stucco walls. The ceiling panels are mostly intended for suspended ceilings in office cooling, heating and other commercial applications.

Why has this trend of radiant ceilings and walls emerged and grown so tremendously in Europe over the past decade?

One reason for the popularity of radiant wall heating definitely has to do with the popularity of tile stoves, which originated in Alpine countries like Switzerland, Austria and Bavaria, and spread to the northern part of Germany and Scandinavia.

The radiant comfort experienced by users of old fashioned massive tile stoves, which have been built into homes over centuries, have definitely been a driving force. Anybody who has ever sat next to one of those beautiful monster stoves on a cold winter day knows what they are raving about. Why the renaissance of radiant tile stoves as a form of wall heating?

Besides the comfort issue, the reasons are mostly economics. Radiant comfort in Europe certainly doesn’t have to be promoted as a novelty any longer. Over the past 50 years, modern day hydronic radiant heating technology has established itself to the point where most Europeans have become accustomed to it as part of their daily lives.

A hydronic radiant system is certainly easier to retrofit into walls at a fraction of the cost of floor systems. Only one third of the material is needed, since walls can run at higher supply water temperatures, typically between 80°F to 150°F, and even higher temperatures if needed a few days out of the year. Radiant comfort is not affected by it but enhanced, in my opinion.

All this is possible, since we are not designing the system around a maximum floor surface temperature of 85°F as in radiant floor systems. Should we get occasional wall surface temperatures of 90°F – 110°F, it doesn’t matter — you can’t thermally overload the wall because we are not walking on it.

Radiant walls can also be an excellent auxiliary surface in conjunction with radiant floors, which many of you have utilized in the past in bathroom installations and in high heat loss areas. Radiant walls are also a great combination with new or existing HVAC systems, providing the contractor with a radiant tool without breaking your client’s bank.

The basics

In order to keep system cost at a level to sell radiant comfort to the rest of your lower budget projects, follow these basic installation rules:

Rule No. 1: Based on the room’s heat loss, design the square footage wall panel area around 50 Btuh/sq.ft.

Rule No. 2: Use low-cost manifolds without circuit shut offs and balancing valves and balance the system by utilizing equal circuit lengths (±20-ft.) and reverse return piping to supply your wall tubing.

Rule No. 3: Tie manifolds into existing supply and return lines of an old copper fin tube section or radiator connection on retrofit/remodeling applications. Sometimes that can save you a lot of supply and return piping cost, if your heat source is remotely located. Or replace old piping with PEX tubing.

Rule No. 4: In conjunction with HVAC systems, select rooms or living areas, where people “live” and can enjoy the radiant warmth. Living rooms, kitchens, bathrooms, finished basements, gyms, bonus rooms over garages, etc. — a wall panel in the garage will make your car battery happy during the winter.

Rule No. 5: Keep the control strategy simple! Use a simple digital thermostat to turn the circulator on and off or, better yet, leave it running and cycle a dedicated heat source off and on, like an electric or condensing boiler. Forget about mixing valves, outdoor reset controls and fancy piping schematics. An expansion tank, a circulator and heat source tappings for supply and return water will do.

If you combine a wall system with a high temperature heat source, you might consider a manual or non-electrically controlled mixing valve that you can “set and forget.”

Don’t use DHW tempering valves; they are not made for this application.

Rule No. 6: Tie into existing heat sources, like heating boilers or DHW tanks. In conjunction with HVAC systems, use small electric boilers or dedicated water heaters, gas or electrically heated. Use side-arm or internal heat exchangers on new or existing DHW tanks to provide warm water to the walls, where codes don’t allow direct connection to a water heater.

After determining the square footage of wall panels needed for a given room, which should not be more than one-third to half of its floor space, utilize outside walls first for your panel installation.

Make sure the outside walls are insulated according to code (usually R-19). If there is insufficient outside wall space to meet the heat load, use interior walls. Use only the bottom half of the walls (4-ft. from the floor) first, and all areas under windows. For typical heat losses, the bottom half of two walls of a room are usually sufficient.

For example: A room 20-ft. x 20-ft. with two walls covered 4-ft. in height translates into 160-sq.ft. of wall panels, or 40% of the room’s floor space. A panel output of 50 Btuh/sq.ft. translates into 8,000 Btuh output capacity at 150°F water temperature under design conditions. That would be equivalent to 20 Btuh/sq.ft. of that same room's floor area (400-sq.ft.) in floor heating terms. Yet we are providing only 40% of the floor's heat emission surface area. If your heat loss requirements are higher or lower, adjust your wall panel radiator surface area up or down accordingly.

If you should oversize the wall panel area, your system will operate at lower water temperatures and vice versa.

The beauty of radiant walls is that there are no heat output restrictions to be dealt with, as they exist with carpets, wood flooring, area rugs, etc. What the panel is rated for is what you get out into the room. All objects in the room become radiation heat sinks. Even the adjacent floor area becomes a heat storage radiator and floor surface temperatures are tempered as well.

The first question you will always be asked by your client is: Can I hang pictures or a flat screen TV on the wall without puncturing the tubing. The answer is yes.

You can locate the tubing with a thermo-sensitive foil tape, which is attached to the finished wall. These should be available through your panel supplier, or use an infrared thermometer or thermal imaging device.

Taking a photo of the wall with the tubing exposed and a marked measuring stick as an additional simple tubing location method.

If a tubing puncture should occur, it can be easily repaired with PEX tubing couplings.

In most cases the tubing panels are installed only 4-ft. up from the floor, half way up the wall. This eliminates concern about hanging pictures in the top half of the wall area.

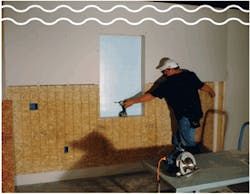

When screwing sheetrock or cement board over the wall panels, caution must be taken by marking the tubing runs and U-bends. Sheet rock or cement board can be cut into 2-ft. x 8-ft. strips. As you are working your way up the wall, it will keep the tubing more visible.

Keep your wall panels with tubing runs 6-in. off the floor; that will prevent wooden baseboard nailing accidents. The installation requires mostly a common sense approach, not much different from radiant floor installations.

Once the system is operating during the first cold spell, the client will love you with radiant warm feelings and thank you for such a comfortable system and for not breaking the bank!

Let’s not keep hydronic radiant wall heating an industry trade secret any longer. Try out a system this season. You and your customer will love the ease of system installation and its great performance.

Joe Fiedrich is a former hydronic heating columnist for CONTRACTOR. He was the president of Stadler Corp., which is now part of Viega North America, and he is the inventor of the Viega Climate Panel and Uponor Quik Trak. He can be reached at [email protected].